Actuators play a pivotal role in various industries, from robotics to aerospace, by converting energy into mechanical motion. They stay as the integrative parts that facilitate motion to systems and thus guide through the efficiency and precision level. Hydraulic, pneumatic, electrical, and piezoelectric actuators are examples of these, all with different aspects that best suit them for specific applications. Knowing how an actuator works and what its capabilities are is quite critical to acquiring optimal performance and desired results in many fields.

Table of Contents

ToggleKey Takeaways

- While choosing actuators, the requirement or need for the load capacity, speed, and precision should be taken into account.

- Know the types of actuators available, hydraulic, pneumatic, electric, and mechanical, including when to apply which one.

- Choose actuators targeted at particular application requirements, considering environmental conditions, space constraints, and safety considerations.

- Regular maintenance and monitoring of the actuator are important in order to extend its life and avoid unexpected failures.

- Proper training on the handling of actuators should be given to personnel to ensure their safe operation and for achieving maximum efficiency.

- Actuator selection that aligns with your exact needs, properly maintained, will drive improvements in productivity while minimizing potential downtime.

Key Factors for Actuator Selection

Identify Movement Type

Actuators can provide linear, rotary, or oscillatory motion depending on the application that demands them. The kind of movement is very important to be known while selecting the appropriate actuator.

- Linear actuators move in a straight line.

- Rotary actuators rotate around an axis.

- Oscillatory actuators move back and forth, repeating the same motion over time.

Evaluate Precision Needs

Tolerance is a requirement in most mechanisms for applications where precision is necessary. Having high precision actuators ensures high positioning and repeatability accuracy for applications that use, for instance, robotic surgeries.

- High precision actuators have minimal backlash.

- Low precision actuators may be suitable for less critical applications.

Consider Energy Input

Different actuators require different energy inputs. Electric actuators are very efficient, but sometimes they need a power source. However, pneumatic actuators will do very well if applications include application-side compressed air.

- Electric actuators are energy efficient.

- Pneumatic actuators are cost-effective for air-powered systems.

Force Requirements Assessment

The force requirements will vary depending on the respective application, and knowing what exact force output your application requires will help in selecting an appropriate actuator that could handle the workload effectively.

- Heavy-duty actuators are basically meant for high-force applications.

- Light-duty actuators find their niche applications that are to require a lesser force.

Types of Actuators

Electric Actuators

Electric actuators are designed to convert electrical energy into mechanical movement directly. The industries that application of electric actuators extends to include robotics, automotive systems, and machinery. Electric actuators provide accurate control, high efficiency, and easy integration with automation systems.

automation systems.

Pros:

- Precise positioning

- Low maintenance

- Quiet operation

Cons:

- Higher initial cost compared to other types

- Limited power output for heavy-duty applications

Electric actuators are devices that use an electric motor to drive the motion. Depending on applications, they are capable of producing either linear or rotary motion. They find their applications in systems requiring precise positioning and control, as used in medical equipment and aerospace technologies.

Pneumatic Actuators

Pneumatic actuators work with the motion of compressed air. These kinds of actuators have wide application in industries that require simple, clean, and less expensive devices. The actuators are used in manufacturing plants, assembly lines, and systems of transportation.

- Simple design

- Cost-effective

- Fast response times

Pneumatic actuators have a fast response time, and can generate large forces rapidly. Therefore, pneumatic actuators are applied in areas which involve fast motion processes like in pneumatic drills and robotic arms.

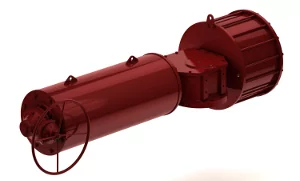

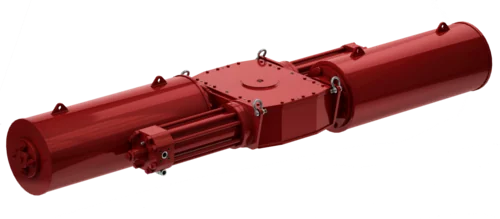

Hydraulic Actuators

Hydraulic actuators function by utilizing pressurized fluid to create motion. These actuators are commonly used in heavy-duty applications that require substantial force output. Hydraulic actuators are prevalent in construction equipment, marine systems, and aerospace machinery.

- High force output

- Suitable for heavy-duty tasks

- Smooth and consistent motion

Hydraulic actuators are used based on the principle that the pressure of the fluid is directed to achieve motion. Used for this reason, they become potent for suited heavy-duty applications. Hydraulic actuators play a crucial part in most construction equipment, marine systems, and machinery units making up the aerospace field.

Application-Specific Considerations

Speed and Distance

Actuators will come in different speed ranges and distances; these are two major factors that help one choose between actuators in an application. One would prefer linear actuators in applications requiring very fine control over distance since they offer linear motion. Rotary actuators are used where a continuously rotating action has to be developed, as in conveyor systems.

The speed of hydraulic actuators is expected to yield large forces at relatively slower speeds compared to electric actuators. Electric actuators provide higher speed and very fine control over position, making them perfectly suitable for applications where fast response times are required.

Operating Environment

The operating environment is important factor to choose an actuator. For instance, in extremely harsh environments, high and low temperatures may be experienced. In cases of exposure to chemicals, more robust actuators like pneumatic actuators are preferred because they can withstand such environmental factors. The electric actuators are used in clean environments and where precision and silent operation are required.

The stainless steel actuators are used in most corrosive environments since they do not rust or corrode. Furthermore, dust and ingress of water into electrical enclosures are avoided by IP-rated actuators for better performance in extreme conditions.

Mounting Style

Mounting style is another key characteristic of an actuator for integration into a system. The actuators may be mounted horizontally, vertically, or even inverted, subject to the requirements of the application. This gives much flexibility in terms of using up available space and efficiently working within any spatial constraints involved with respect to specific applications.

The mounting of actuators should ensure load distribution, easy access for maintenance, and proper alignment in view of other components in order to function smoothly and for a long service life.

Summary

Conclusion

Choosing the proper actuator means taking into consideration key factors of load requirements against speed and precision, entailing an understanding of the types available and the areas of application. Be it hydraulic, pneumatic, electric, or piezoelectric actuators, each type has advantages and limitations that should align with their intended use. Application-specific considerations further narrow down the selection process in providing the best performance and life for the actuator in its chosen application. Looking carefully at each of these factors allows one to make informed decisions on the path to efficient and effective actuator integration.

Any person venturing into the world of actuators will find that consulting the experts at AFC and doing detailed research is very instrumental in getting through the intricacies of this very integral component of many mechanical systems.

Be informed, be curious, and never stop exploring the vibrant world of actuators.

Frequently Asked Questions

What are the key factors to consider when selecting actuators?

The key factors one needs to consider in selecting the most suitable actuators include load requirements, stroke length, and speed, control options, environmental conditions, and compatibility. A good actuator will offer optimal performance depending on whether or not the outlined factors satisfy its requirements.

What are the different types of actuators available?

Actuators are designed in several different fundamental types: electric, pneumatic, hydraulic, and mechanical. Each has its own advantages and application based on unique precision, force output, speed, and in some cases environmental considerations.

How should I determine the most suitable actuator for my specific application?

The correct actuator for your application will be the one that suits the load, speed, and precision required by your application while withstanding the environmental conditions or other space limitations of your application. Consultation with experts at AFC is also recommended to gain some valuable insights.

What are some common application-specific considerations when choosing an actuator?

In choosing the right actuator to be used in a particular application, one considers safety requirements, duty cycle, maintenance needs, integration into existing systems, regulatory compliance, and cost-effectiveness. Making a proper choice based on these considerations will assure optimum performance.

Why is it important to select the right actuator for a system or machinery?

The proper selection of the actuator is very important because it is directly related to the efficiency, performance, and life of a system or any machinery. Proper matching of the actuator with its application provides smooth operation, accurate control, low downtime, energy efficiency, and cost-effectiveness in the long run.